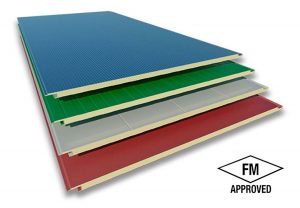

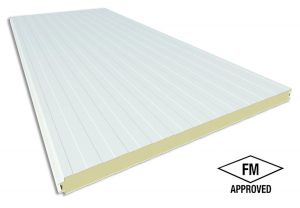

HF Panel

Through an extensive series of tests, Hiansa Panel has obtained certification for two of its products under the prestigious Factory Mutual seal.

Hiansa Panel, a manufacturer of panels with both 4880 and 4881 classifications

Technical details

New core

To achieve this important certification, a new chemical composition of the High Index PIR-FM insulating core has been developed and approved, which has been designed to offer better performance in terms of fire behavior, as well as in its physical-mechanical behavior.

The reticulated cyclic structure of the High Index PIR-FM provides the panel with a high capacity for fire resistance since, in the event of a flame, this foam undergoes a superficial carbonization process that has the following main properties:

- It prevents a fire from spreading.

- It generates low levels of smoke.

- It is self-extinguishing from the moment the fire stops.

Euroclass classification of the CLASS1 FM APPROVED panel according to EN13501-1

In the process of homologation of the new product for the European market (CE marking), HIANSA PANEL has tested this new composition in the laboratories of the notified body AFITI LICOF, obtaining a classification of the panel’s reaction to fire:

B: Very limited contribution to firess1: Low opacity of smoked0: Does not cause flammable drops to fall

This is the maximum classification that an insulating product of this type can obtain according to this standard. The tests carried out to obtain this certification are as follows:

- Small Burner Test (EN11925-2): Application of direct flame on the insulating core.

- SBI test (EN13823): It aims to simulate a small fire, low power (30kW) without fully developing.

HF tests

Approval Standard 4880: CLASS 1 FIRE RATING OF BUILDING PANELS

The behavior of the material tested before the action of fire is subject to a comprehensive series of tests. The most notable of these is the so-called ROOM TEST UBC 26-3.

This test simulates a room built with the materials to be tested, in which a fire is generated in a corner of it since it is the most unfavorable case in a closed location.

In our case, the 200 mm (7.87 in.) thick panel is used for setting up the simulation, since it is the most adverse setup that we can have, due to the greater mass of foam contained.

This room has dimensions of 2.44 m (8.01 ft) x 2.44 m (8.01 ft) x 2.44 m (8.01 ft).

The source of flame generated has an approximate power of 500 kW, reaching temperatures of 1,000 ºC (1832 ºF).

The fire has a duration of 15 minutes during which the material must demonstrate that:

- There is no spread of fire.

- There is no carbonization greater than 2.5 cm (0.98 in.) at the core of the panel.

- There is a low smoke generation.

- Self-extinguishing the fire when the flame is no longer applied.